GET THE FACTS

Understanding the Science and Scope of Hydraulic Fracturing

Black Mountain Energy is a natural resource company focused on developing and operating natural gas projects in Western Australia.

Black Mountain Energy safely advances and commercialises unconventional reservoirs, forging a path for a responsibly developed natural gas supply.

Our work balances energy production with environmental stewardship, leveraging technology to minimize impact and maximize efficiency.

Stay informed with the latest announcements, company updates, and key documents from Black Mountain Energy — all in one place.

We deliver the facts on hydraulic fracturing with transparency and science, backed by decades of experience and rigorous regulation.

GET THE FACTS

Understanding the Science and Scope of Hydraulic Fracturing

Hydraulic fracturing, or “fraccing”, is a method used to extract oil and gas from deep rock formations. With more than 100 years of combined experience across our team, we understand the science behind it and the responsibility that comes with it.

We know trust isn’t automatic and when information comes from the source, it can feel biased. This is why you’ll find independent sources and scientific research to back up our facts. Energy isn’t isn’t a one-size-fits-all debate – it’s all of the above. But that conversation only works if we cut through assumptions, throw out misinformation, and focus on facts.

So here’s what fraccing really involves: how it works, what goes into it, and what happens after. Oil and gas is one of the top five most heavily regulated industries in the world, and we’re proud of the discipline and transparency that comes with that.

Hydraulic fracturing is a technique that increases the flow of oil and gas from rock formations by creating tiny fractures deep underground. These fractures are held open by sand or ceramic materials, allowing natural gas to flow to the surface. And it’s not new. Hydraulic fracturing has been used safely and effectively worldwide since 1947 and, in Western Australia since in 1958.

Read more here about what fracturing stimulation is, and the differences between coal seams, tight gas, and shale gas.

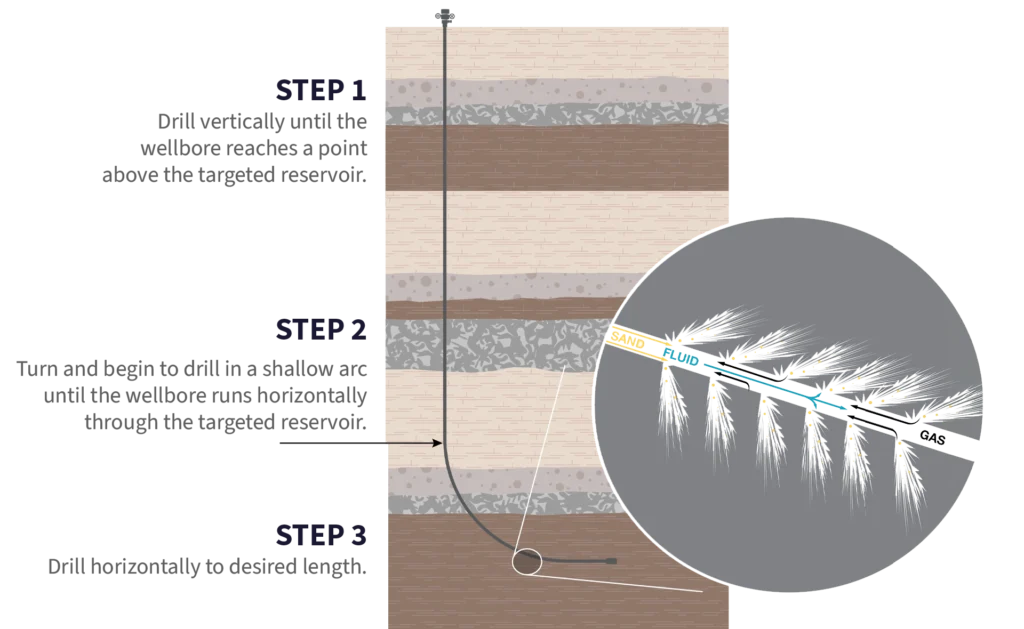

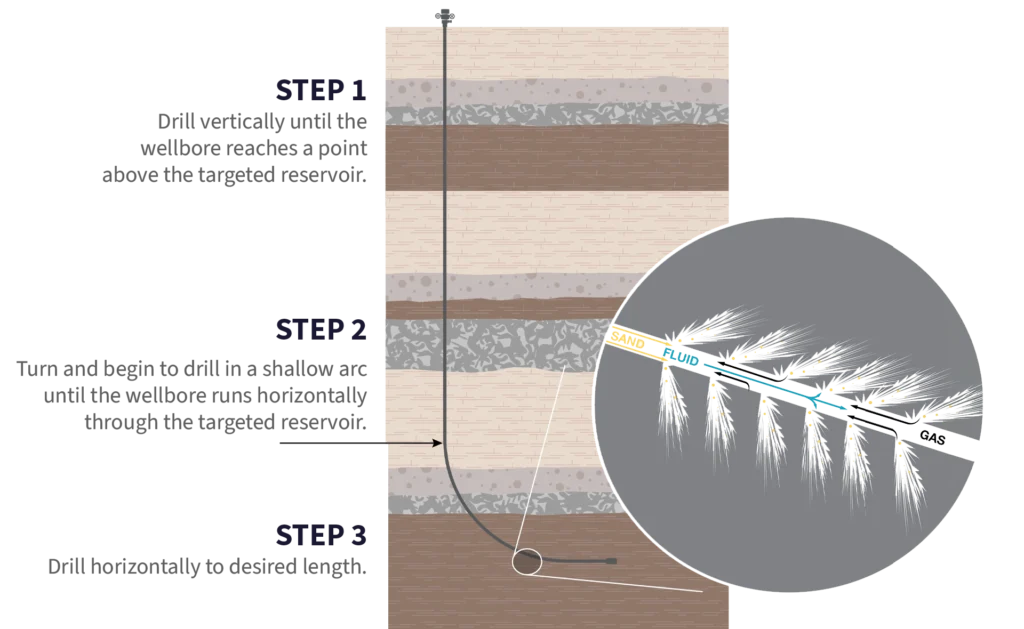

A well is drilled vertically, then horizontally through the gas-bearing rock. Fracturing fluid is pumped at high pressure into the well, creating microfractures (typically 3–6 mm wide) that extend up to 400 m horizontally and 100 m vertically.

Well integrity is essential. Each well includes multiple layers of steel casing and cement to protect groundwater and isolate the gas reservoir. All wells undergo pressure testing and real-time monitoring during operations.

Monitoring includes:

• Seismic mapping

• Tiltmeters for surface movement

• Water bore monitoring

• Temperature logging and non-radioactive tracers

Read more here about how wells are constructed and managing the risks from fracture stimulation.

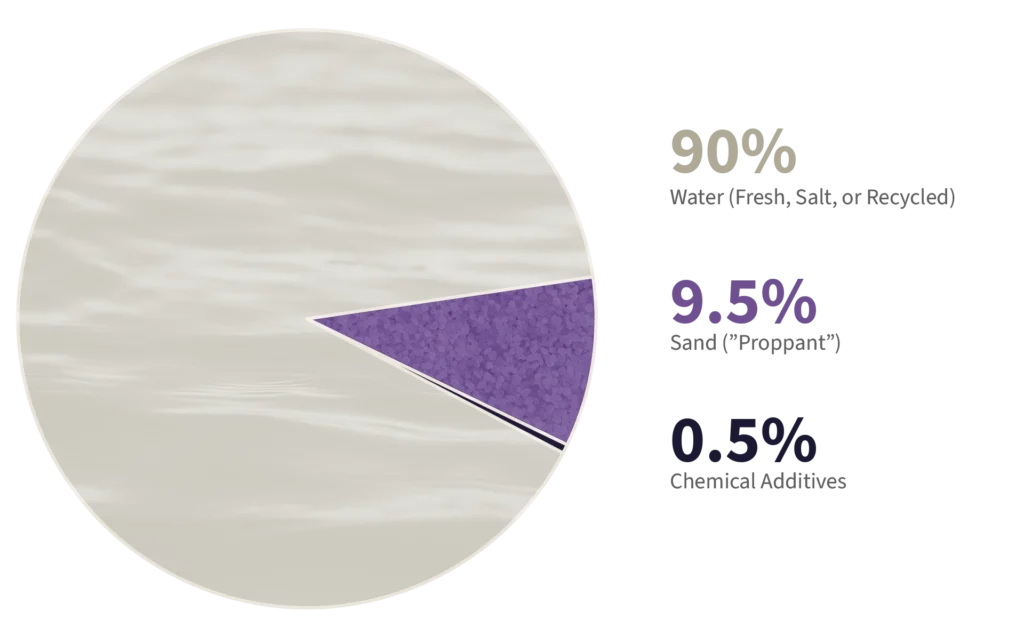

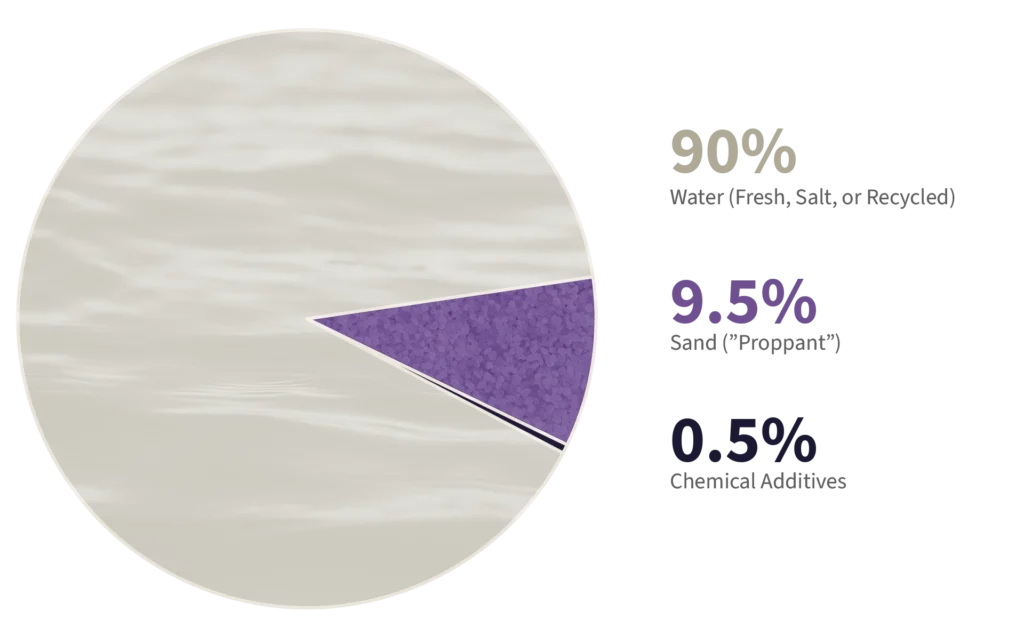

The fluid used in fraccing is primarily water and sand:

90% Water – Fresh, salt, or recycled water can be used. Water is the carrier fluid that creates the pressure needed to open tiny fractures in the rock and to transport the sand and additives deep into the formation.

9.5% Sand (Proppant) – Specifically graded sand is used to “prop” the fractures open. This increases the amount of natural gas that can be extracted.

0.5% Additives – These include food-grade or biodegradable agents that thicken water, reduce friction, prevent corrosion inside the well, and stop bacterial or mineral build-up. None are carcinogenic, environmentally persistent, or permitted to contain BTEX chemicals in Western Australia.

All additives are publicly disclosed and must be pre-approved by the WA Government. Up to 80% of fluids are recovered after the fraccing process, stored in lined and bunded ponds, and either reused in another well or allowed to evaporate safely under strict environmental regulations.

Read more here about frac chemicals and additives and water usage required for drilling and fracture stimulation.

Hydraulic fracture stimulation at sites like Project Valhalla typically lasts 1 to 10 days per well. Following completion:

• Most equipment is removed;

• The site footprint shrinks from ~2 hectares to as little as 0.4 hectares;

• Gas can flow to pipelines for 20–40 years;

• After production ends, wells are sealed and the site is fully rehabilitated.

Fracture stimulation may occur during the exploration, evaluation, or production stages of a project.

Read more here about project lifecycle and how we are regulated.

FACT: Used since 1947; over 2.5 million global applications

FACT: No confirmed cases in Western Australia; wells are sealed and isolated

FACT: Produces micro-seismic events – smaller than a truck driving by

FACT: Water use is <1% of WA’s municipal water, and occurs once – not continuously

FACT: Natural seeps existed long before fraccing was used

Read more about common Myths vs Facts.

Hydraulic fracturing, or “fraccing”, is a method used to extract oil and gas from deep rock formations. With more than 100 years of combined experience across our team, we understand the science behind it and the responsibility that comes with it.

We know trust isn’t automatic and when information comes from the source, it can feel biased. This is why you’ll find independent sources and scientific research to back up our facts. Energy isn’t isn’t a one-size-fits-all debate – it’s all of the above. But that conversation only works if we cut through assumptions, throw out misinformation, and focus on facts.

So here’s what fraccing really involves: how it works, what goes into it, and what happens after. Oil and gas is one of the top five most heavily regulated industries in the world, and we’re proud of the discipline and transparency that comes with that.

Hydraulic fracturing is a technique that increases the flow of oil and gas from rock formations by creating tiny fractures deep underground. These fractures are held open by sand or ceramic materials, allowing natural gas to flow to the surface. And it’s not new. Hydraulic fracturing has been used safely and effectively worldwide since 1947 and, in Western Australia since in 1958.

Read more here about fracturing stimulation and the difference between coal seams, tight gas, and shale gas.

A well is drilled vertically, then horizontally through the gas-bearing rock. Fracturing fluid is pumped at high pressure into the well, creating microfractures (typically 3–6 mm wide) that extend up to 400 m horizontally and 100 m vertically.

Well integrity is essential. Each well includes multiple layers of steel casing and cement to protect groundwater and isolate the gas reservoir. All wells undergo pressure testing and real-time monitoring during operations.

Monitoring includes:

• Seismic mapping

• Tiltmeters for surface movement

• Water bore monitoring

• Temperature logging and non-radioactive tracers

Read more here about how wells are constructed and managing the risks from fracture stimulation.

The fluid used in fraccing is primarily water and sand:

90% Water – Fresh, salt, or recycled water can be used. Water is the carrier fluid that creates the pressure needed to open tiny fractures in the rock and to transport the sand and additives deep into the formation.

9.5% Sand (Proppant) – Specifically graded sand is used to “prop” the fractures open. This increases the amount of natural gas that can be extracted.

0.5% Additives – These include food-grade or biodegradable agents that thicken water, reduce friction, prevent corrosion inside the well, and stop bacterial or mineral build-up. None are carcinogenic, environmentally persistent, or permitted to contain BTEX chemicals in Western Australia.

All additives are publicly disclosed and must be pre-approved by the WA Government. Up to 80% of fluids are recovered after the fraccing process, stored in lined and bunded ponds, and either reused in another well or allowed to evaporate safely under strict environmental regulations.

Read more here about frac chemicals and additives and water usage required for drilling and fracture stimulation.

Hydraulic fracture stimulation at sites like Project Valhalla typically lasts 1 to 10 days per well. Following completion:

• Most equipment is removed;

• The site footprint shrinks from ~2 hectares to as little as 0.4 hectares;

• Gas can flow to pipelines for 20–40 years;

• After production ends, wells are sealed and the site is fully rehabilitated.

Fracture stimulation may occur during the exploration, evaluation, or production stages of a project.

Read more here about project lifecycle and how we are regulated.

FACT: Used since 1947; over 2.5 million global applications

FACT: No confirmed cases in Western Australia; wells are sealed and isolated

FACT: Produces micro-seismic events – smaller than a truck driving by

FACT: Water use is <1% of WA’s municipal water, and occurs once – not continuously

FACT: Natural seeps existed long before fraccing was used

Read more about common Myths vs Facts.

For learn more about our work in the Canning Basin, please visit our Project Valhalla page.

Black Mountain recognises Aboriginal and Torres Strait Islander peoples as Australia’s first peoples. We acknowledge the unique connection that First Nations peoples have to land, waters and the environment. We extend this recognition and respect to First Nations peoples and communities around the world.

For learn more about our work in the Canning Basin, please visit our Project Valhalla page.

Black Mountain recognises Aboriginal and Torres Strait Islander peoples as Australia’s first peoples. We acknowledge the unique connection that First Nations peoples have to land, waters and the environment. We extend this recognition and respect to First Nations peoples and communities around the world.